Performed works

The lifting of the pleasure boat "Līgo"

Winter cold, thick ice, and harsh weather conditions became the cause of the flooding of the "Ligo" pleasure boat. After the request for help, divers wasted no time and began the challenging and responsible task of raising the sunken vessel. Before commencing the main work, the divers thoroughly inspected the hull of the ship and discovered several breaches that had caused its flooding. The ship sank at a depth of 3.5 meters with a bow trim of 8 degrees and a port list of 16 degrees.

The dimensions of the ship's hull were approximately 22 meters in length and 4 meters in width. To restore the watertightness of the ship's hull, divers started patching up the breaches. Then, a complex procedure of pumping out the water from the vessel began. Divers started working using special pumps and equipment. With each passing minute, the ship rose higher and higher. Eventually, thanks to the divers' perseverance and experience, the "Ligo" resurfaced. Upon seeing the ship afloat, the participants in the salvage operation felt pride and satisfaction in their work. This moment became a true triumph for the team of divers whose efforts and hard work yielded concrete results.

The successful completion of the salvage operation of the sunken vessel "Ligo" was due to the professionalism of the ASPTR diving team. They demonstrated a high level of expertise and strict adherence to environmental standards throughout the complex operation. This case confirms the importance and indispensability of divers in the rescue and recovery of underwater objects, as well as emphasizes the need for careful environmental stewardship during such work.

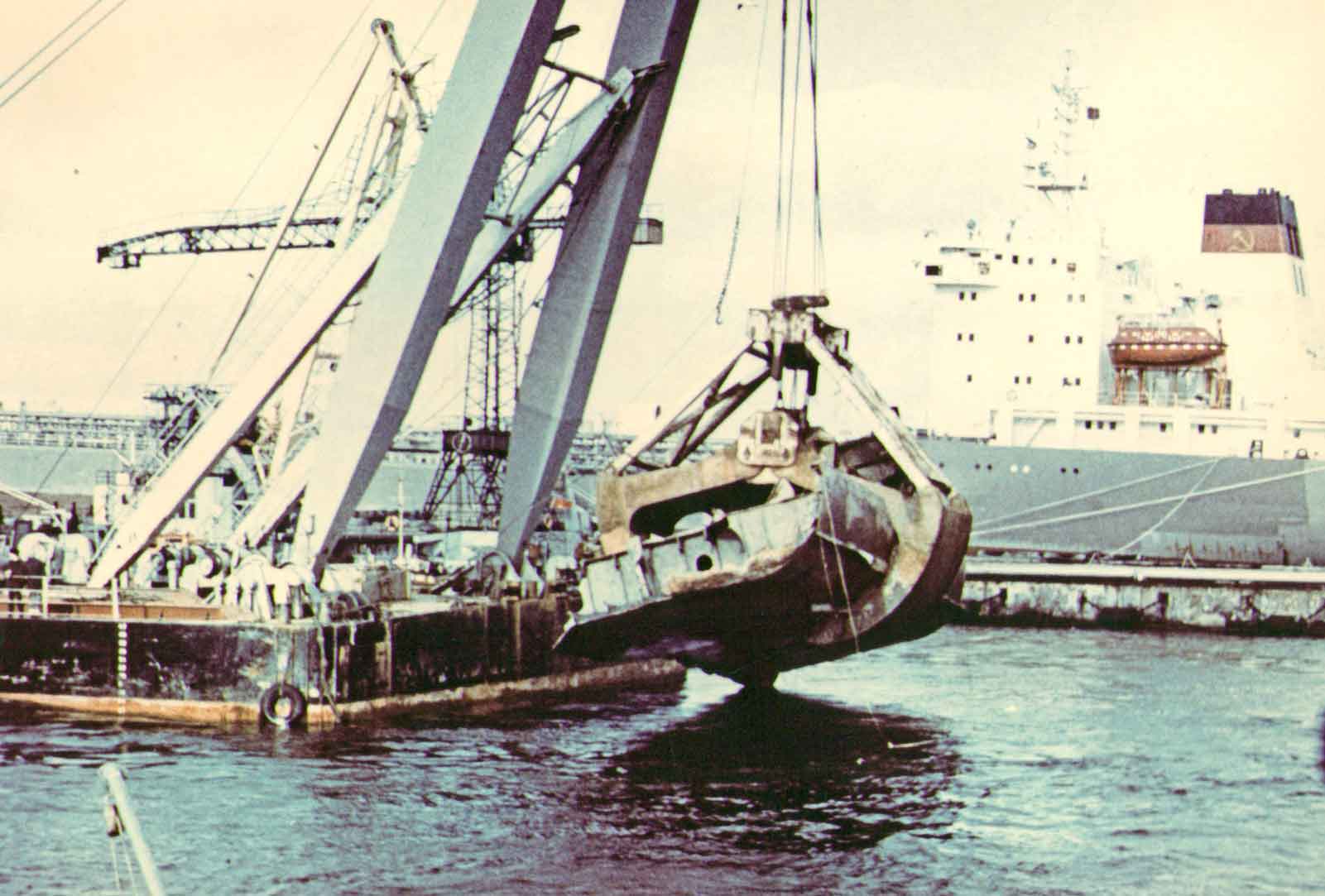

Barge Lift

There was a strong north wind in one of the Latvian ports. A gust of wind created a large roll of the barge, as a result of which the cargo shifted, the barge lost its stability and turned over. She drowned at a shallow depth of 9 meters.

ASPTR divers, as a result of an underwater survey, found a large hole in the barge's hull.

After evaluating the damage to the hull, ship recovery specialists decided that the barge should be lifted in parts. In accordance with the project, the divers set to work. The hull of the barge was cut in two using oxy-fuel cutting and special cutting chains. After separation, the divers proceeded to pressurize the surviving compartments.

And with the help of a floating crane, they began to lift the barge. At 22:49 the first part of the barge was raised to the surface, and a couple of days later at two o'clock in the morning the second.

After ship-lifting work, the company began cleaning up the water area of the berth. All work was carried out in compliance with environmental safety standards.

Training Exercises of the Ferry "Romantika"

During the rescue training exercises of the ferry "Romantika" in November 2009 at the port of Riga, the diving company "ASPTR" ensured the recovery of sunken items. Basically, such items were special mounts for life-rafts weighing 300 kg. The difficulty was that the organizers of the exercises severely limited us in time. In 30 minutes, the divers had to find mounts of life-rafts at the bottom, then sling and lift to the surface, while the rescue exercises did not stop, they had to work practically under the ship. To ensure the successful completion of the task set, “ASPTR” specialists have developed a special lightweight system for quick lifting of large items weighing up to 450 kg, for the use by one diver in light diving equipment. Using this system, all sunken items were raised. On the first day of the training exercises, 2 life-rafts mounts and on the second day, 1, with a total weight of 920 kg. Thanks to the well-coordinated operation of “ASPTR” divers, during the exercises the ferry remained on the line and made scheduled voyages to Sweden.

Ship Merkur Lifted out of Water

In 1997, when ship Merkur was towed from Tallinn to Klaipeda, water started flowing into machine space leading to the ship lurched considerably. Since at that moment the ship was not far from Ventspils Port, captain of the tugboat applied for permission to enter the port to pump out water. Before the team of specialists arrived, the ship had considerably lurched to the left and getting over berth, it sank at 9 m depth and listed 500. After unsuccessful attempt of company V to lift the ship, real threat occurred that Merkur would get to the port shipway with depth reaching 12,5 m. That was the reason why Latvian Maritime Administration entered into the agreement with company ASPTR to lift ship Merkur. The group of professionals equipped with relevant diving, search-and-rescue equipment and vehicles was formed. Specialists decided to use block-and-cable system to prevent the situation. After the ship hull became waterproof and water inflow was prevented, pumps of total capacity 900 m3/h were installed in the ship sections. With the ship being gradually lifted out of water, the block system pressed it to the berth wall. It took 26 hours to recover the ship floatability, after which it was delivered to the customer and towed to the Port of Klaipeda.

The project for lifting the ship was developed by engineer Jevgenijs Morozovs.

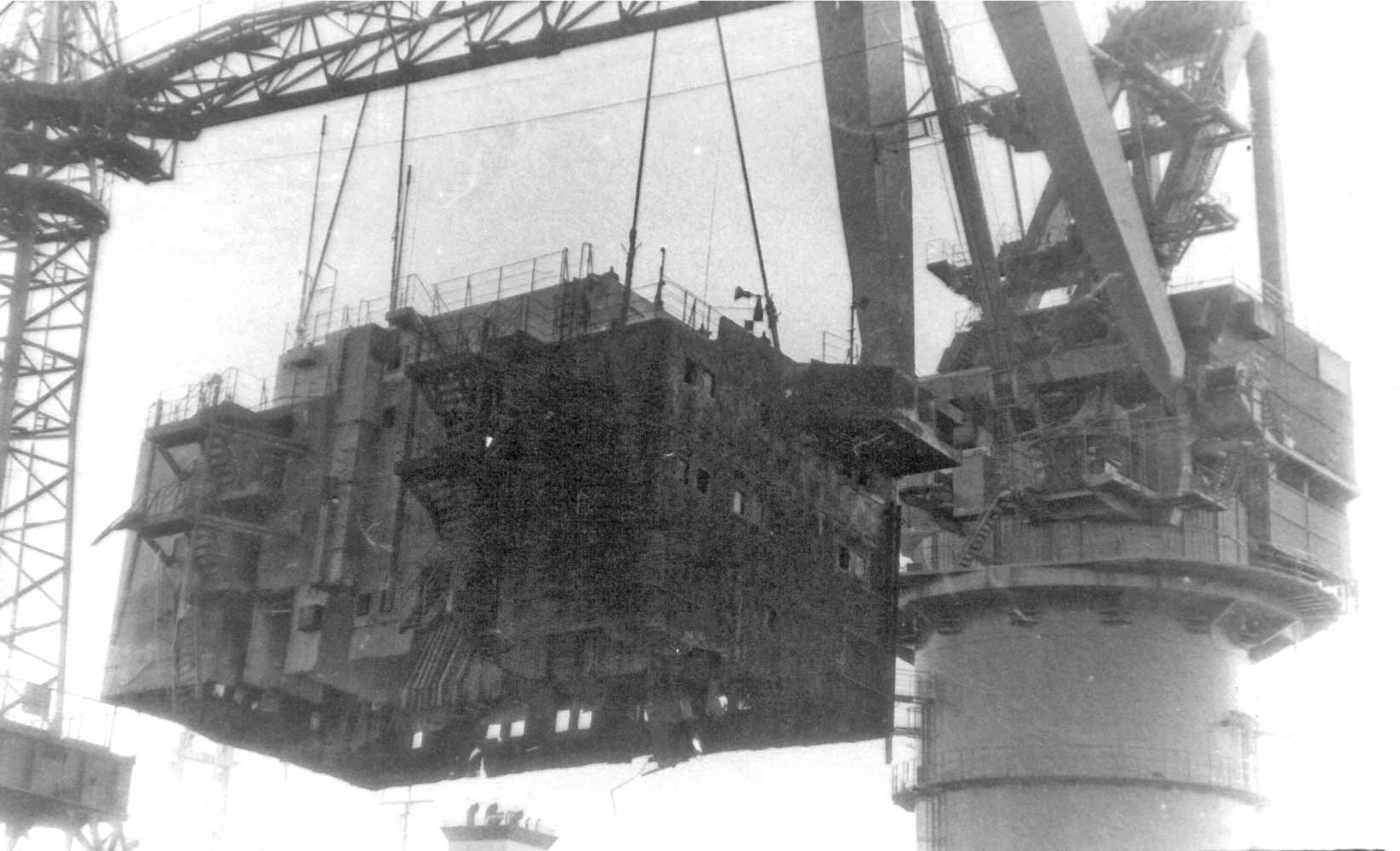

Work Performed for Tanker Ludwig Svoboda at Ventspils Sea Port

In March 1985, at Ventspils Sea Port berth, tanker Ludwig Svoboda exploded. 4 members of the crew died. The ship was completely destroyed, except its back section. Front section was detached. The hull central section terribly deformed was at the bottom of water area; back section partially connected to the hull remained afloat.

Riga group of ASPTR had to perform the following tasks:

Search and raising of died members of the crew;

Raising of ship parts out of water that were destroyed due to explosion to resume operation of Venta navigation way and adjacent berths;

Disjointing of the ship-hall;

Detachment of the ship back section from the hull to reconstruct and use the same later on.

Work was performed within eight months. More than 3000 tons of metal were lifted out of water, 2600 m hull parts were disjointed under water, using electric oxygen and plasma cutting equipment. Cut-off hull parts weighing to 500 tons each were raised by crane barges Titan, Titan 2, Stanislav Judin and Sudopodjom.

Managers of the project were Director of ASPTR Riga group Georgijs Nikolajevs, diving specialist Aleksandrs Dadukins, divers Nikolajs Lugovenko, Viktors Jakovlevs, Georgijs Zenkovs, Igors Nevskis, Nikolajs Domanickis, Uldis Kazainis, etc.

Sunken Floating Workshop Lifted out of Water

A 900 ton floating workshop was at the sea bottom at the Port of Liepaja in the area between the ship repair yard and the sugar factory for 20 years. It sank with lurch to the right and stern lowered into depth of 9 m. Upper part of the structure was seen out of water only.

In autumn 2002, on the basis of company BMGS order, preliminary work to raise the floating workshop out of water began. Company ASPTR specialists decided to lift the workshop, using a combined approach. Stern was connected to the previously submerged pontoon with raising capacity 400 tons. 6 special pontoons with lifting capacity 25 tons each were installed in the central part. It was decided to dry forebody and central sections by pumps installed along waterproof partitions on both sides. During the process of water pumping, specialists faced a problem due to submerged deck section, which they had to strengthen and make waterproof, putting in their best licks. 30 hours were needed to recover the workshop floatability.

Specialists representing company Opron Shipping helped to pump out water. Aleksandrs Dadukin was responsible for lifting operations.

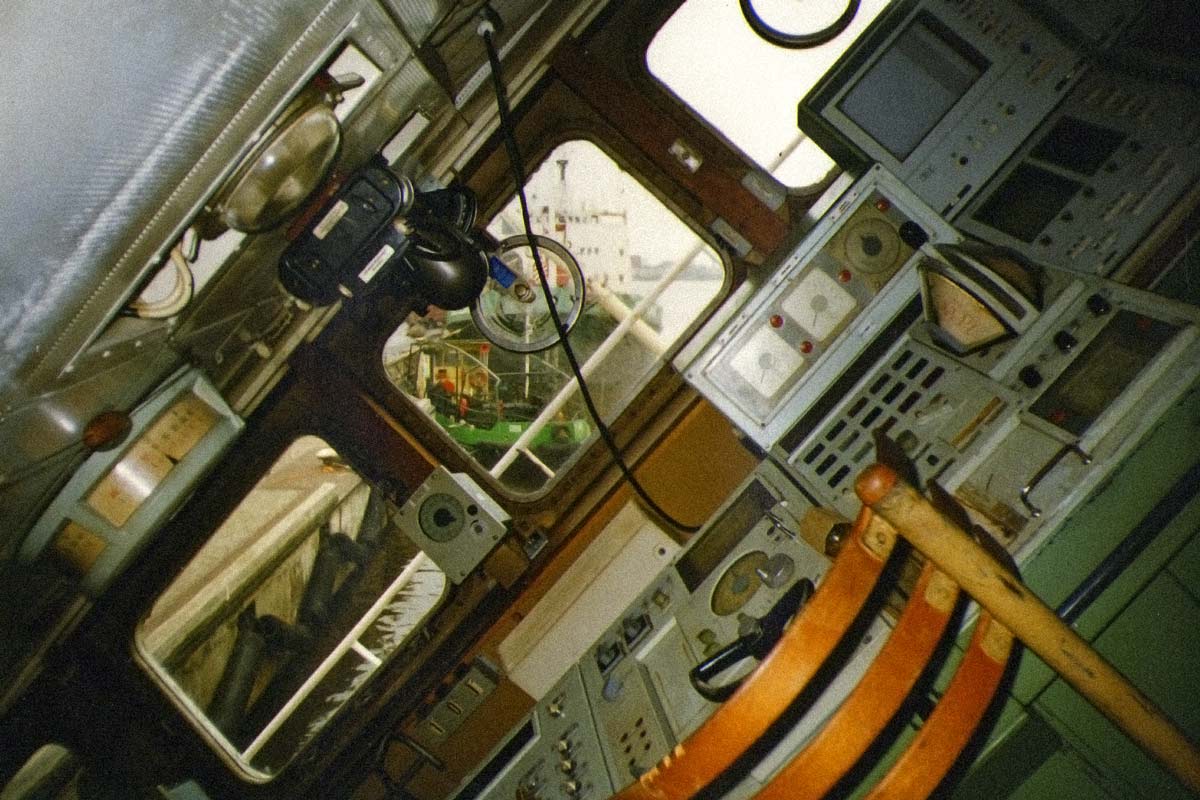

613-Series Submarine Lifted out of Water

In 1998, after the Soviet Army and the Navy left the military base in Bolderaja due to various reasons, three 613-series diesel submarines (classified by NATO as WHISKEY) turned to be sunken. One of them was for military purposes, the second one was used for training purposes and the third one was reconstructed to charge accumulators under water.

The military submarine was at 9 m depth, two others – at 7 m depth with lurch from 15 to 30 degrees to the left. Problems were relating to hermetic sealing, since the hull was overfilled by various pipelines, balloons, etc., preventing divers from detecting the hull holes and sealing them. After water inflow through shafts and hatches had been stopped, drying operations were performed, using electric pump. Work was completed after four months and submarines were delivered for further utilization.

Liquidation of Oil Spill Consequences Resulted from Ship Tern Accident

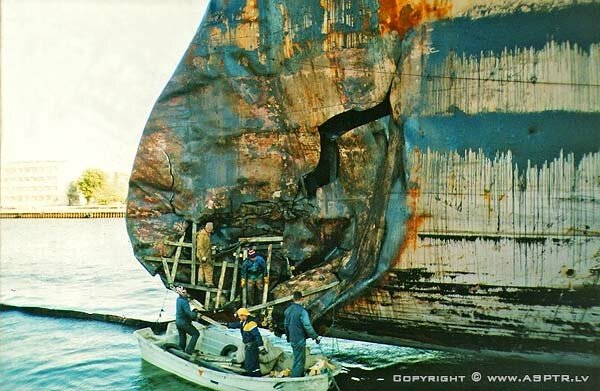

Collision between dry-cargo vessel Tern and the tanker transporting fuel oil resulted in more than 50 tons of fuel oil filled the stern sections. While being unloaded, fuel oil entered the ship forebody damaged area. The ship crew failed to obtain permission for leaving the Port of Ventspils for Klaipeda ship-repair yard due to probable oil pollution of the sea.

Company ASPTR entered into the agreement with the ship owner and the insurance company on prevention of oil spill. It was decided to repair defects, using timber strips, planks, to install soft canvas patch with absorbing layer and to cover all forebody damages by waterproof and gasoline-resistant coating.

All operations were performed timely and ship Tern headed for Klaipeda under its own power. No oil spill was detected while the ship was en route.

Work was performed by Company ASPTR in cooperation with Opron Shipping specialists.

Explosion-Dangerous Items Removed from Liepaja Port Berth

In spring 1999, company ASPTR received an order to survey Liepaja Port 5th berth area 140x10 m and remove any explosion-dangerous items. After careful survey of the water area bottom, divers found various items: a car, a wagon, various metal structures, however such items as depth bombs, various caliber charges, warshot torpedo part, ship heat-protective charges, etc. were detected most often. Divers, acting with greatest care, lifted all such items out of water, delivering them to land guards for classification and further destruction. Two-week operations resulted in 1500 kg ammunition with 600 kg explosives lifted out of water. Moreover, divers also raised various metal structures of total weight 3,5 tons.

Mine Exploder No 530 Lifted out of Water

Mine exploder No 530 sank in Military Channel at Liepaja Port. In 2002, company ASPTR specialists started lifting operations. With low water level, 20 cm of exploder forebody was above water surface only. After defects of the deck, the hull and partially preserved upper structures had been remedied, specialists were able to start water pumping and recovery of the ship floatability. To prevent ship lurching during water pumping, a 10 ton block and rope system installed ashore was fastened to the ship. After all defects had been repaired, cofferdam was installed on the ship forebody. Along with water pumping, specialists sealed inconsiderable cracks. As soon as forebody rose to the surface, pumps were moved to stern sections, with water gradually pumped out of all sections. Pumping operations lasted for 28 hours and having risen to the surface, the ship was towed to shore.

Aleksands Dadukins was responsible for all diving operations.

STB 1026 Search-and-Rescue Operations

the more water was pumped out, the more lurch sideways was observed. With lurch reached 500 , two special pontoons with lifting capacity of 10 tons each were installed under the hull on the right to prevent the mine-sweep overturning. After pontoons had been emptied, specialists continued water pumping operations with the ship lurch being 360. Soon the ship rose to the surface with lurch reduced to 110. Upon completion of water pumping operations, the mine-sweep with 60 lurch was towed to the Port of Ventspils by ship BM-13.

Search-and-rescue operations were performed by divers: Mihails Rjabovs, Eduards Silajevs, Aleksandrs Dadukins, BM-13 captain Vladimirs Anufrijevs and others.